How to Fix Fish Eyes in Epoxy Updated

How to Fix Fish Eyes in Epoxy

This mail may comprise affiliate links. We may earn a pocket-size committee from purchases made through them, at no additional cost to you lot.

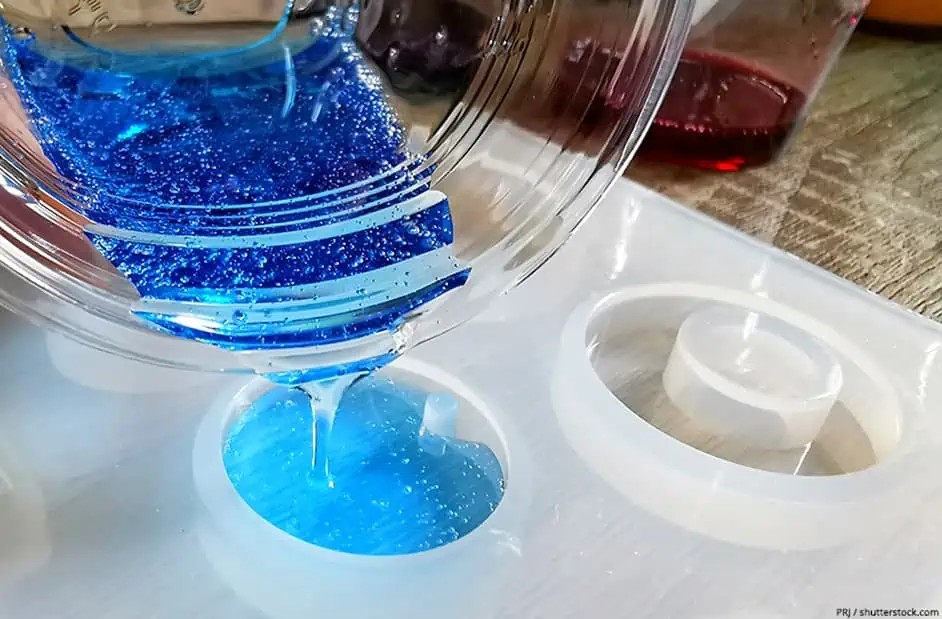

Working with Epoxy is not exceedingly hard, but it doesn't hateful you lot won't brand whatsoever mistakes, even if y'all are a professional person. So, in this article, we will exist profitable you lot on how to set up or repair your epoxy mistakes. Bear in mind that it is easier to repair or fix any mistakes while the epoxy is still wet. When epoxy hardens, it takes a lot more effort to fix the trouble. The adept news is that by applying a second glaze, in most cases, normally fixes even the worst mistakes.

Table of Contents

- ane Mutual Epoxy Mistakes

- 2 How to prepare an uneven Epoxy Resin Finish

- three Trying to prevent those uneven Epoxy Finishes

- 4 Repairing your Epoxy Resin Countertop

- v How to become rid of Ripples and Waves from your Epoxy Surface Finish

- 6 Epoxy Mixture failed to cure after recommended Curing Fourth dimension had elapsed

- 7 Epoxy failed to bond

- 8 Coat Coat Epoxy Problems

- ix Sticky or tacky Epoxy

Mutual Epoxy Mistakes

Non mixing the Epoxy correctly

Most Epoxies are sold in two-office component kits and need to be mixed before you utilise them. The mixing ratio is of vital importance and must exist strictly adhered to. Some epoxy mixing instructions specify that you mix it past weight and others by book. You need to have careful annotation of these instructions. If you brand a mistake in the mixing ratio, you will find that your epoxy will harden likewise apace or too slowly, and worst of all not harden at all.

Selecting the wrong Production

This tin exist disruptive, every bit epoxy products are very versatile. Some are used as a bonding agent, others as molding, casting compounds, structural fillers, or for electronics and much more. Brand certain you select the right production that is suitable for your projection. For choosing the right product, check out our article about the best Epoxy Resin for your project.

Accept not considered the Weather

When you are working with epoxy, temperature always plays an of import role. Almost all of the epoxies comply with a temperature range that governs how information technology cures properly. If you piece of work outside of these temperature ranges, your epoxy can neglect past curing too soon, likewise belatedly, or non at all.

The Storage is non proper

When not using your epoxy, it should be stored at a temperature between sixty° F and 70° F (16° C and 21° C). When the temperature fluctuates too much, it causes the epoxy to crystalize or solidify.

Surface Preparation was inadequate

Earlier applying your epoxy, it is of utmost importance y'all fix your surface properly. Your surface needs to exist make clean, gratis from oil and dry. Declining to do this can lead to your epoxy not bonding or adhering to the surface.

How to fix an uneven Epoxy Resin Finish

Near all the epoxy resins y'all tin purchase are cocky-levelling. However, if you find your epoxy resin is not levelling out properly, it could hateful you are using too piffling resin. This is how you fix your uneven epoxy resin mistake. Besides, ensure that your piece of work surface is level. If you do encounter an uneven finish with your epoxy resin, how can go near fixing information technology?

A good rule to follow is to mix a picayune bit more epoxy than you lot need, ensuring you embrace your surface completely. So, if your epoxy has already cured properly, you lot will demand to sand down the surface and apply a 2d coat. This allows your side by side layer to bail properly. If the epoxy has not fully cured, say afterwards 12 hours or less, all you need to do is pour a second glaze directly over it. Allow this to fully cure, which volition provide you lot with a compatible surface finish.

Trying to foreclose those uneven Epoxy Finishes

The first matter you need to be certain of is, have prepared your surface correctly? There should exist no dirt or grit and it must be perfectly make clean. Next, exist sure that the resin, too as the hardener yous are going to use, is fresh. If you fail to mix or utilise the epoxy correctly, information technology may result in an uneven stop. Therefore, read and follow the mixing instructions properly to avoid or prevent an uneven end.

Repairing your Epoxy Resin Countertop

After a fourth dimension, you will brainstorm to observe that your countertops are peeling or there are scratches on the surface. This is an indication your countertops are due for a repair or bear upon upwardly job. This type of repair is quite easy and can be treated every bit a DIY job, which will relieve yous a great deal of money. Also, by repairing information technology yourself, will give yous great satisfaction. This also belongs to Epoxy Tables .

How to fix your Epoxy Resin Countertop

- To start, yous demand to repair whatsoever deep scratches, peeling or indentations on the surface surface area. To do this you need to embrace all imperfections with approved surface abrasions. Quondam English is a particularly good product that you may consider. Remember, brand sure to follow the instructions properly to ensure you go that clear glass finish.

- Now, you need to sand over all your imperfections including scratches by using a wet/dry out, 650 grit sandpaper. Make sure to sand parallel to all these imperfections. After you are satisfied that your countertop surface is prepare, it needs to be cleaned properly. To do this y'all will need to employ a l/50 cleaning solution consisting of 50% commercial cleaner and 50% water. Brand sure y'all wipe the surface area clean removing all cleaning solution likewise as any clay or grit.

- The next step is to buff the surface of your countertop and apply a thin layer of epoxy, which should seal the surface and restore that clear glass smooth and stop. You now need to wait for at to the lowest degree 24 hours for the epoxy to cure, and then bank check to see if is dry and not gluey. Lastly, take a make clean towel with some alcohol and remove any fries that take formed along the edges of your countertop.

How to get rid of Ripples and Waves from your Epoxy Surface Finish

When you are working with a wood surface, you may discover certain imperfections such every bit ripples, waves, or bubbles. You will find that applying only one coat of epoxy will not be enough, you will need to employ more than than ane coat to set the problem. First, apply a thin coat, this is referred to equally a flood or seal coat. This should exist applied over the unabridged surface at a thickness of 1/8" or (3 mm). Recall, you will be applying your epoxy resin in ii stages. Get-go, the seal glaze, which is a small-scale and thin amount, to help avoid any air bubbles. Adjacent, utilise the bladder coats, this is the same product as your seal coat. This must be adhered to in all the subsequent layers until you reach your levelling goal.

Think, the temperature is ever of import, so be careful to avoid too much heat when y'all remove the ripples or bubbles. As within whatever other epoxy work, be sure to take whatsoever precautions needed such equally working in a well-ventilated area and protecting your peel and eyes.

Epoxy Mixture failed to cure after recommended Curing Fourth dimension had elapsed

The first question that comes to heed is, how long does it take for the epoxy resin to cure? The curing time of resin varies, but don't stress, as all the information you need is included with the resin kit. However, most epoxies volition dry to the touch inside 24 hours, and fully cure within 48 to72 hours. There is a quick-drying resin on the marketplace that cures within 2 hours, but it is not recommended for beginners.

Reason 1 – Mixing Ratio

The principal reason your epoxy did not cure in the desired time, is that the mix ratio was not followed correctly. This means that there was also much, or too little hardener added, which will affect the curing time.

How can you fix this Problem?

- The only sure fashion to obtain a neat finish is to remove the epoxy completely. Do not effort to embrace it over with an additional layer, then begin the process over again.

- Mix the epoxy and hardener thoroughly at the right ratio and but add together fillers or additives afterwards.

Reason two – Temperature

Another aspect affecting the epoxy curing time is temperature. If y'all are working in an area that has a low temperature, it will consequence in a slower curing time.

How tin can you gear up this Problem?

- You volition need to give your epoxy extra time to cure, more than the instructions on your kit.

- You can also apply heat, which assists the chemical reaction and so speeds upwardly the curing process.

- There is a production on the market called 205 Fast Curing Hardener. This product is specially designed to assistance the epoxy cure at lower temperatures.

Reason 3 – Incorrect Products

One final reason your epoxy is non curing correctly is that you may have used the wrong products.

What you tin do to fix it?

- The but sure way to obtain a great finish is to remove the epoxy completely and not try to encompass it over with an additional layer. Then start this process once more.

- When purchasing your epoxy, yous need to take care and check the compatibility of the resin and the hardener. Many resins volition not cure properly if mixed with other brands or with polyester catalysts.

Epoxy failed to bond

There can be several reasons why this happens. Here we volition explicate and endeavour to give y'all the solution to set it. The first reason would be that the epoxy failed to cure properly. Refer to the section above, which should provide you with all you demand to know in this regard.

Another reason, information technology could be the issue of a contaminated surface surface area. Ensure your expanse is thoroughly cleaned and prepared before you apply your epoxy mixture.

Coat Glaze Epoxy Problems

Your epoxy coat could become cloudy. This is referred to as a Glazed Coat Epoxy Trouble.

Reason 1 – Humid Conditions and Moisture

This could be the result of boiling conditions or moisture from condensation, which reacted with the components of your mixture before the epoxy could cure.

How to ready it?

- Try by applying heat to the epoxy blanket in an attempt to remove any wet and allow the epoxy to cure fully.

Reason 2 – Trapped Air in your Epoxy

The problem could be the result of air trapped in your epoxy.

How can I fix it?

- Try applying the epoxy when the temperature is warmer, as epoxy tends to be thinner in warmer temperatures.

- Another method, try and apply your epoxy in thinner coats.

- Apply estrus to the epoxy coating in an attempt to release any trapped air, and let the epoxy to cure fully.

Sticky or tacky Epoxy

Your glazed coat epoxy problem could also leave your epoxy pasty or tacky after leaving it to cure for a few days.

How to fix it?

- The only sure way to solve this problem is to remove the epoxy completely, and practice not cover it over with an additional layer. Endeavour to remove as much equally possible.

- When most of the resin has been removed, you tin can employ a fresh layer of resin.

- Subsequently the get-go coat, allow to cure thoroughly, and then give the surface a very light sanding and wipe the surface area clean.

- Now, you are fix to utilize the second coat.

- If y'all have followed the procedure correctly, your epoxy should cure without having a glutinous or tacky experience to it.

How to Fix Fish Eyes in Epoxy

Posted by: joanshawat.blogspot.com

0 Response to "How to Fix Fish Eyes in Epoxy Updated"

Post a Comment